Reebok

SCAD collaborated with Reebok to research, explore and present back ways in which they could use material scraps, cut-offs, and end-of-roll fabrics to create a sustainable product line.

About

SCAD and Reebok hand-picked 15 students to take part in this Collaborative learning course in which we were split into 3 teams of 5 to develop environmentally conscious products or processes for them to integrate into their line.

Each team had to assign roles for each team member. I was tasked to be the Project Manager for my team which involved keeping everyone on schedule, presenting back work to stakeholders and keeping a line of communication open with key stakeholders at Reebok for the duration of the project (2.5 months). In addition, I also volunteered to be the Documentation manager for the whole class, which required documenting the whole process for this project from all 3 teams, and creating the final deliverables for our stakeholders: presentations (initial and final) and process book.

Design Process

We continually change the way we work to adapt to the ever changing demand in our products. But below, I have listed out the steps we typically follow each season when dropping a new collection and have shown examples of each:

Project Briefing

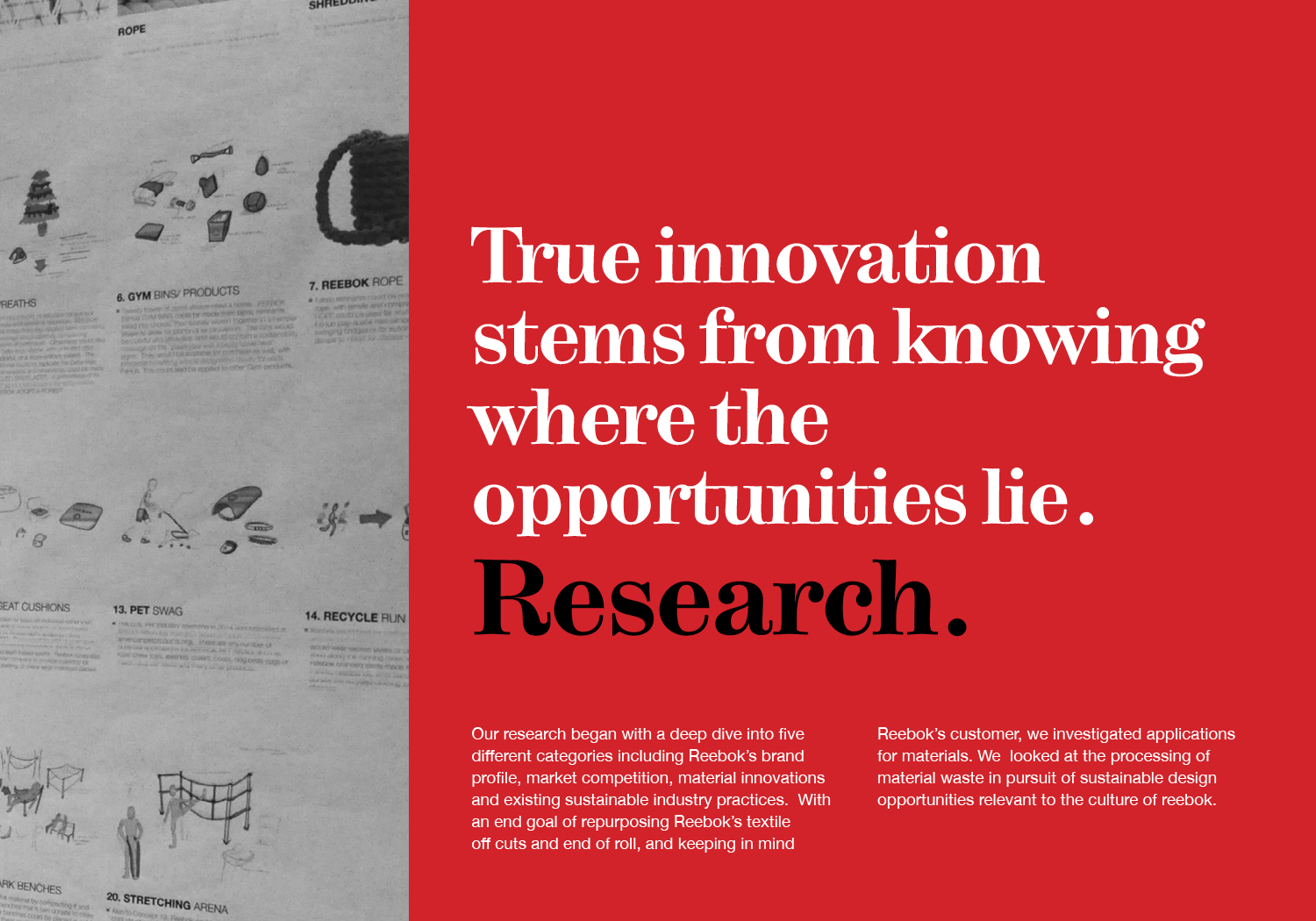

During this ten week journey, we researched and ideated ways in which reebok could repurpose their waste and excess materials and create new products or raw materials for their core line through a sustainable product line.

Research + Ideation

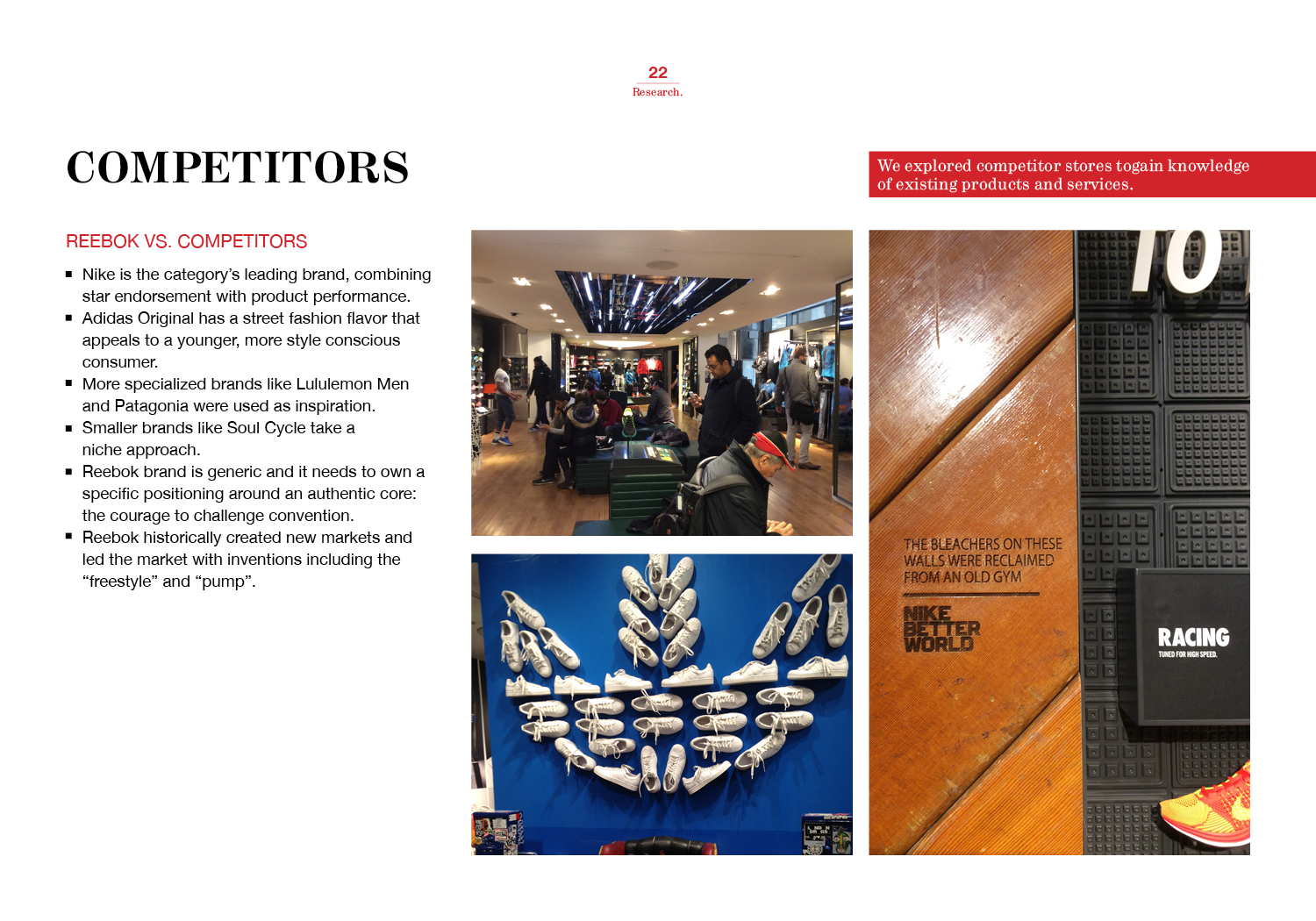

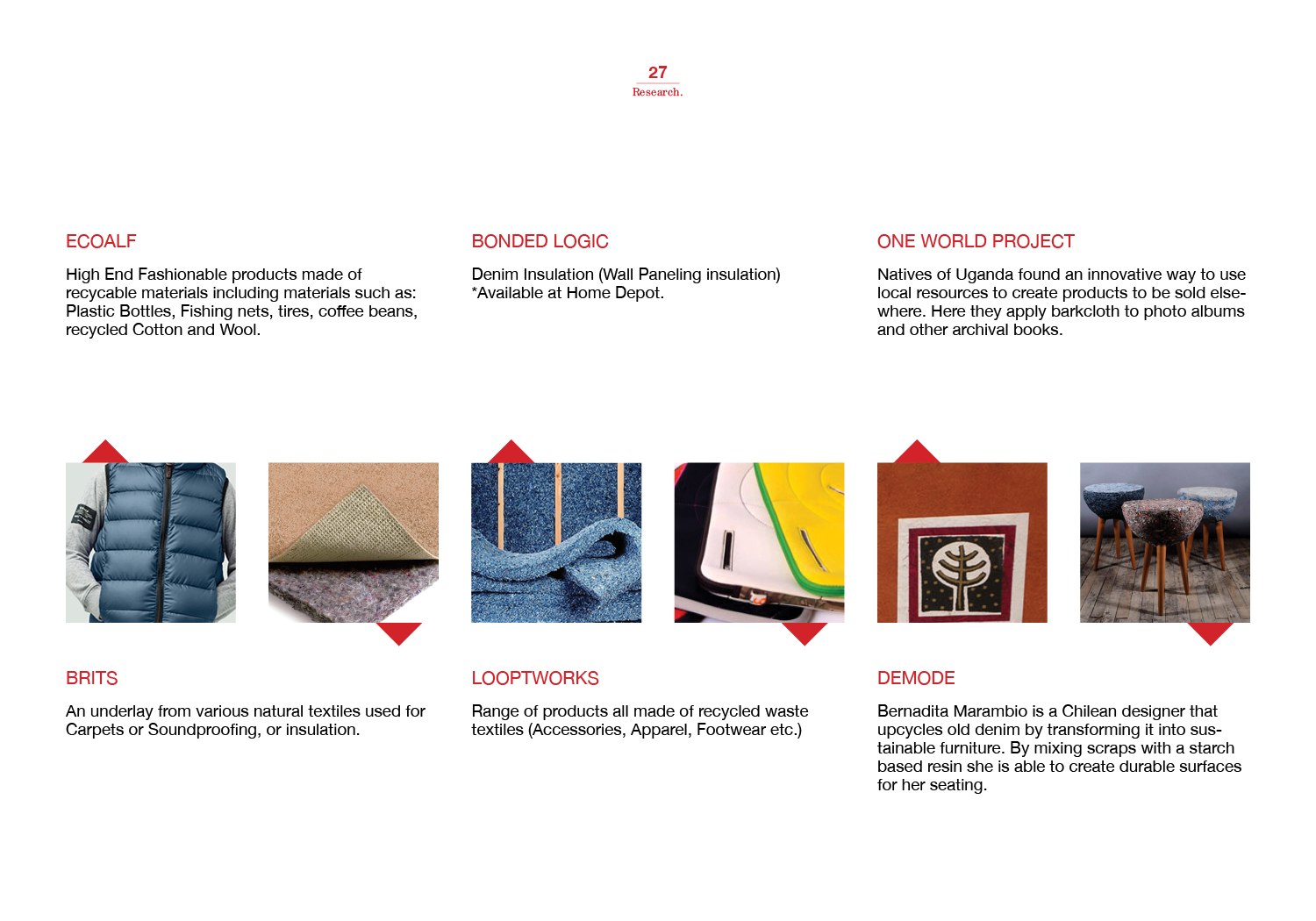

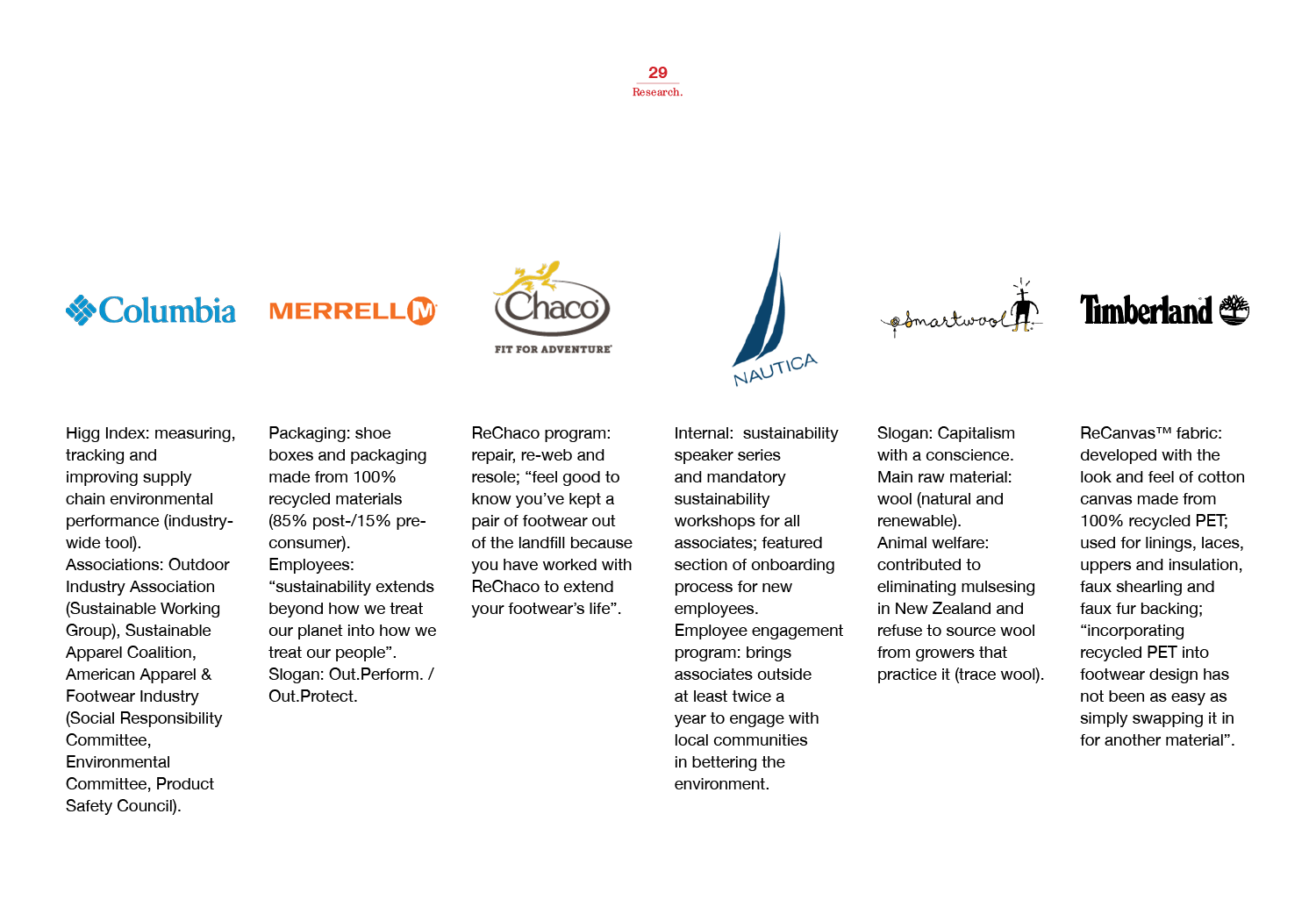

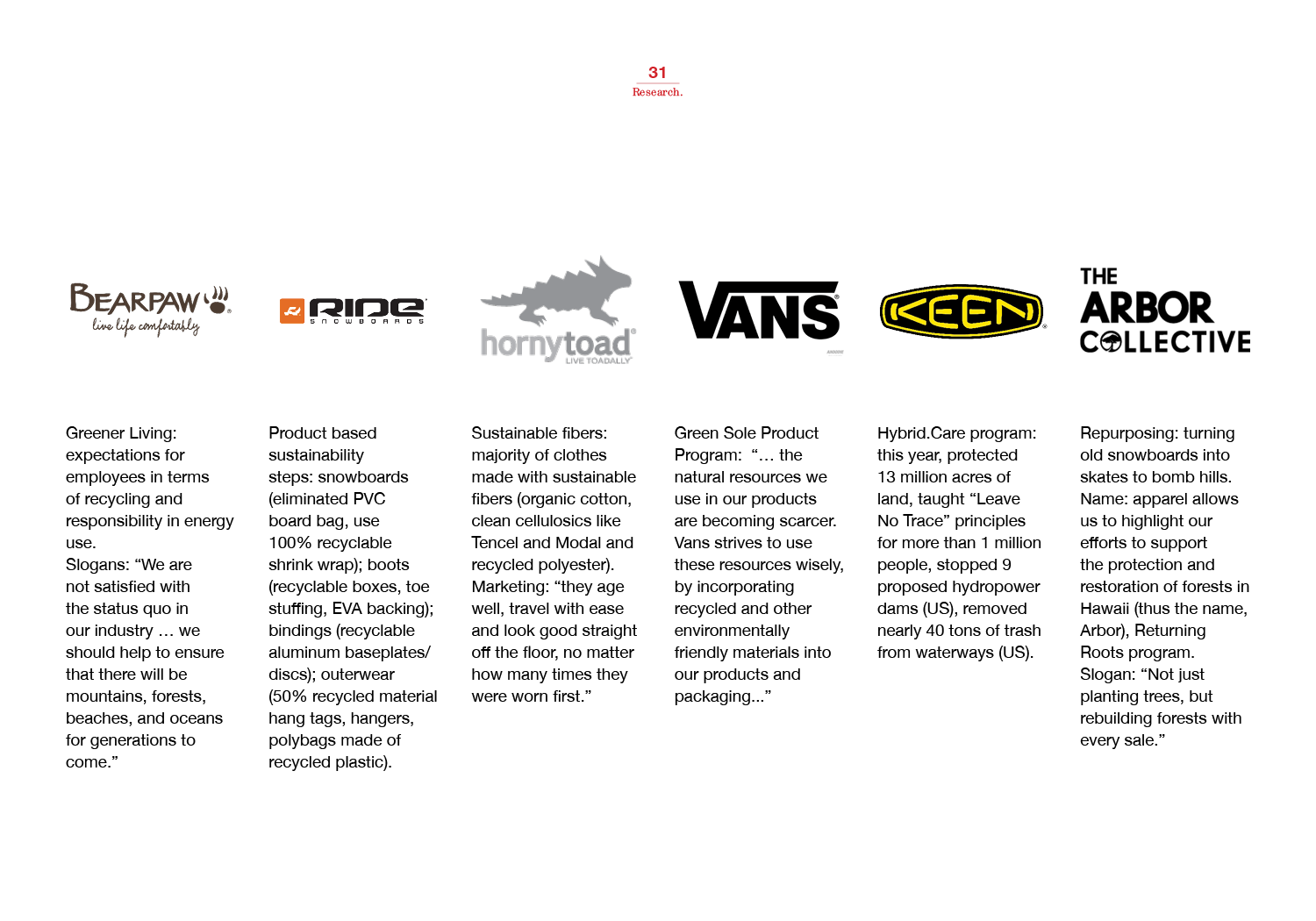

At first we had to do some primary research to outline what their competitors were doing to keep a sustainable approach in their designs

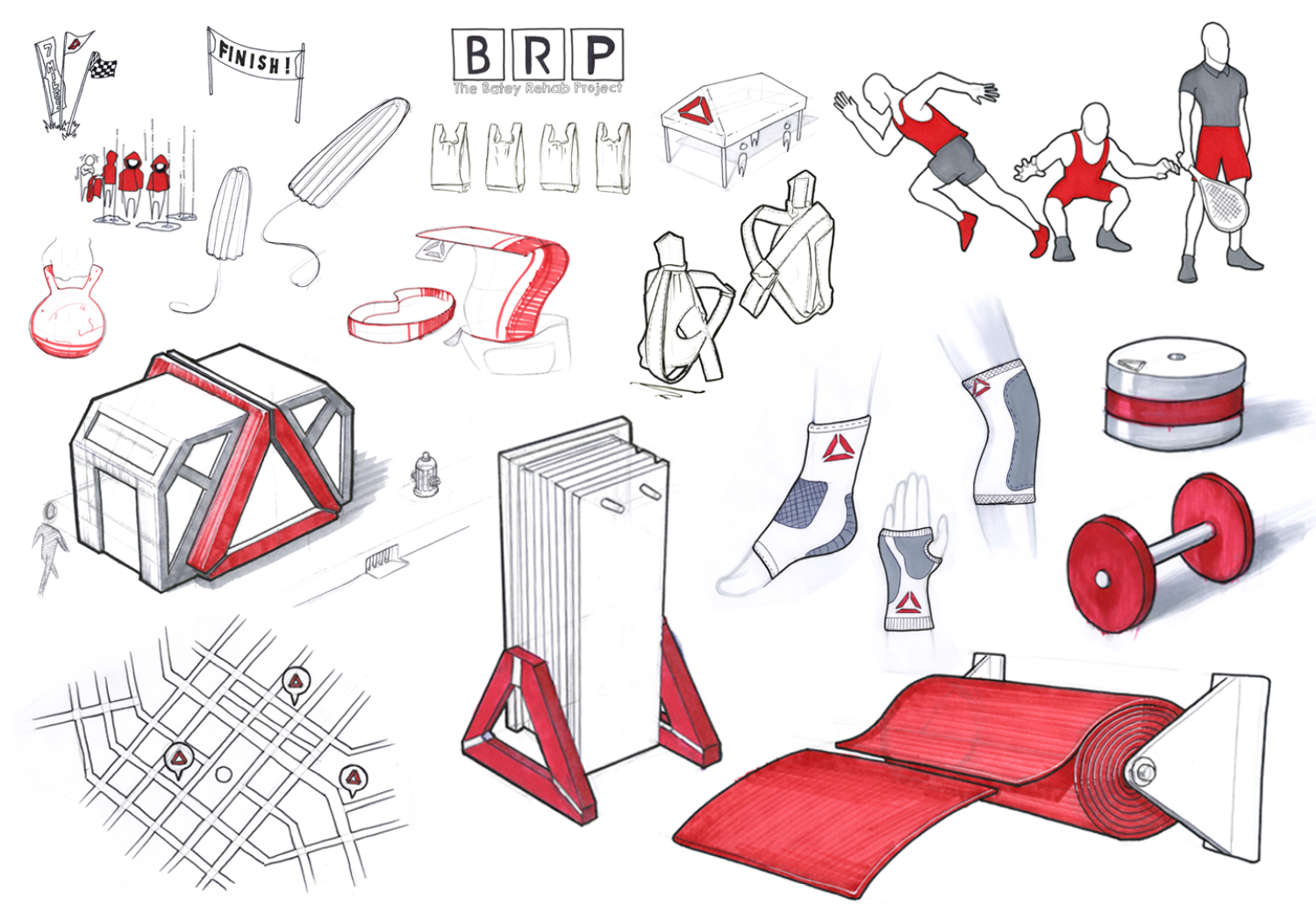

Afterwards, we came up with more than 50 different ideas detailing ways in which we could create sustainable processes or products that they could include in their production and product cycle.

Development + Handoff

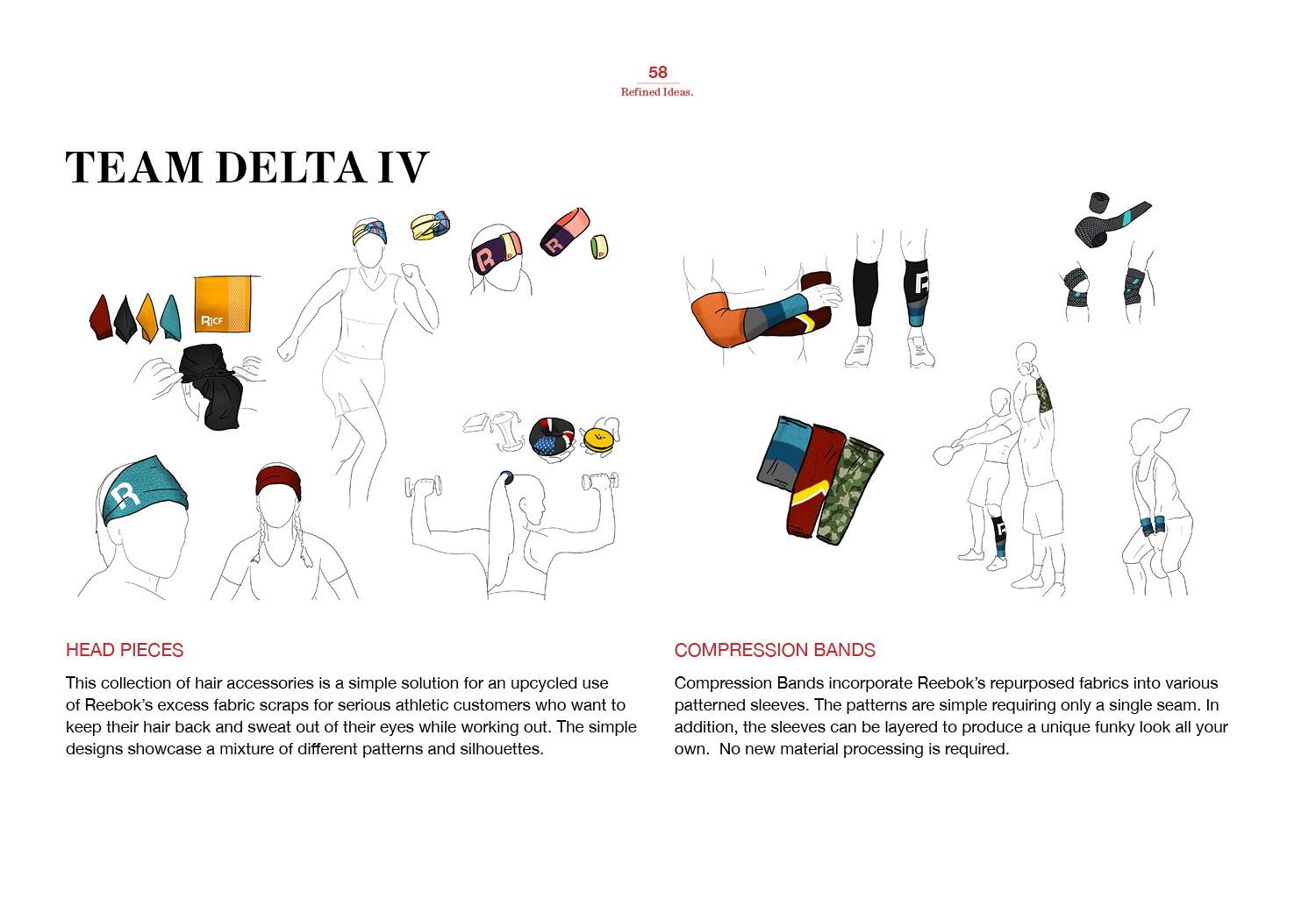

After showing all the research and preliminary ideas to the stakeholders, we then narrowed them down to a smaller cluster of options for us to dive deeper and design into.

We then created a curated set of options for the Reebok stakeholders to then narrow down even further. After this exercise we were able to come up with a succinct plan to develop a line of accessories and apparel that featured details made out of end of roll fabrics.

Documentation

Visual Inspiration

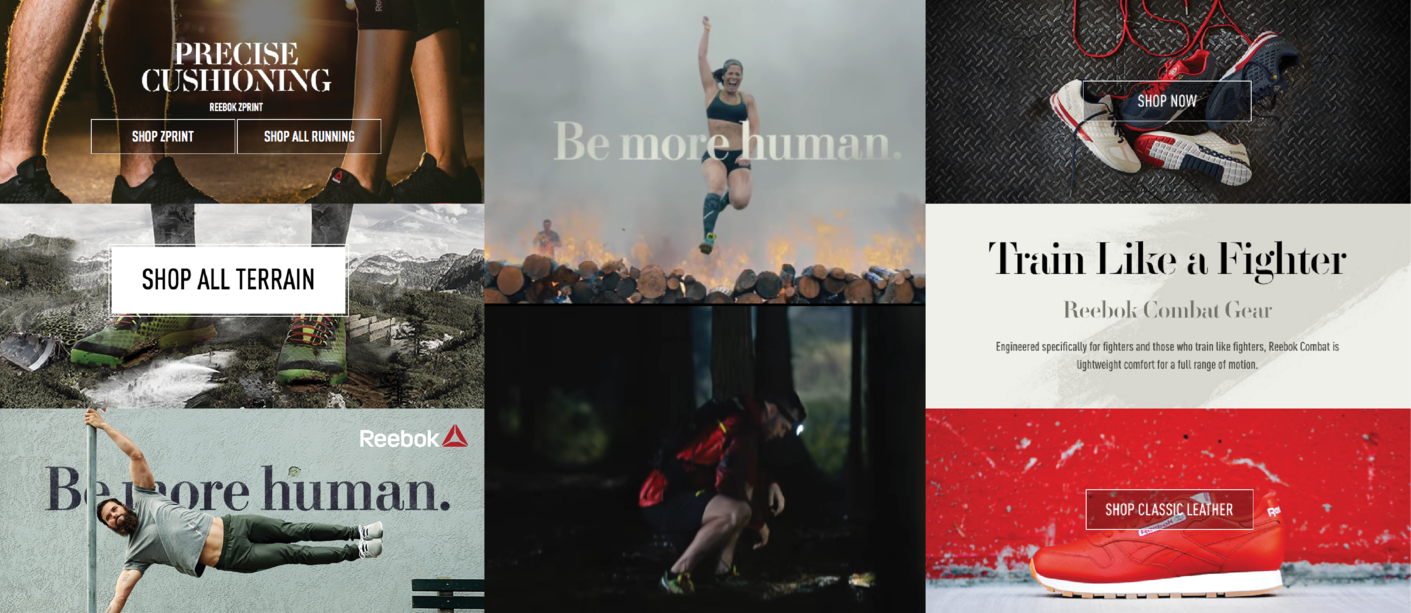

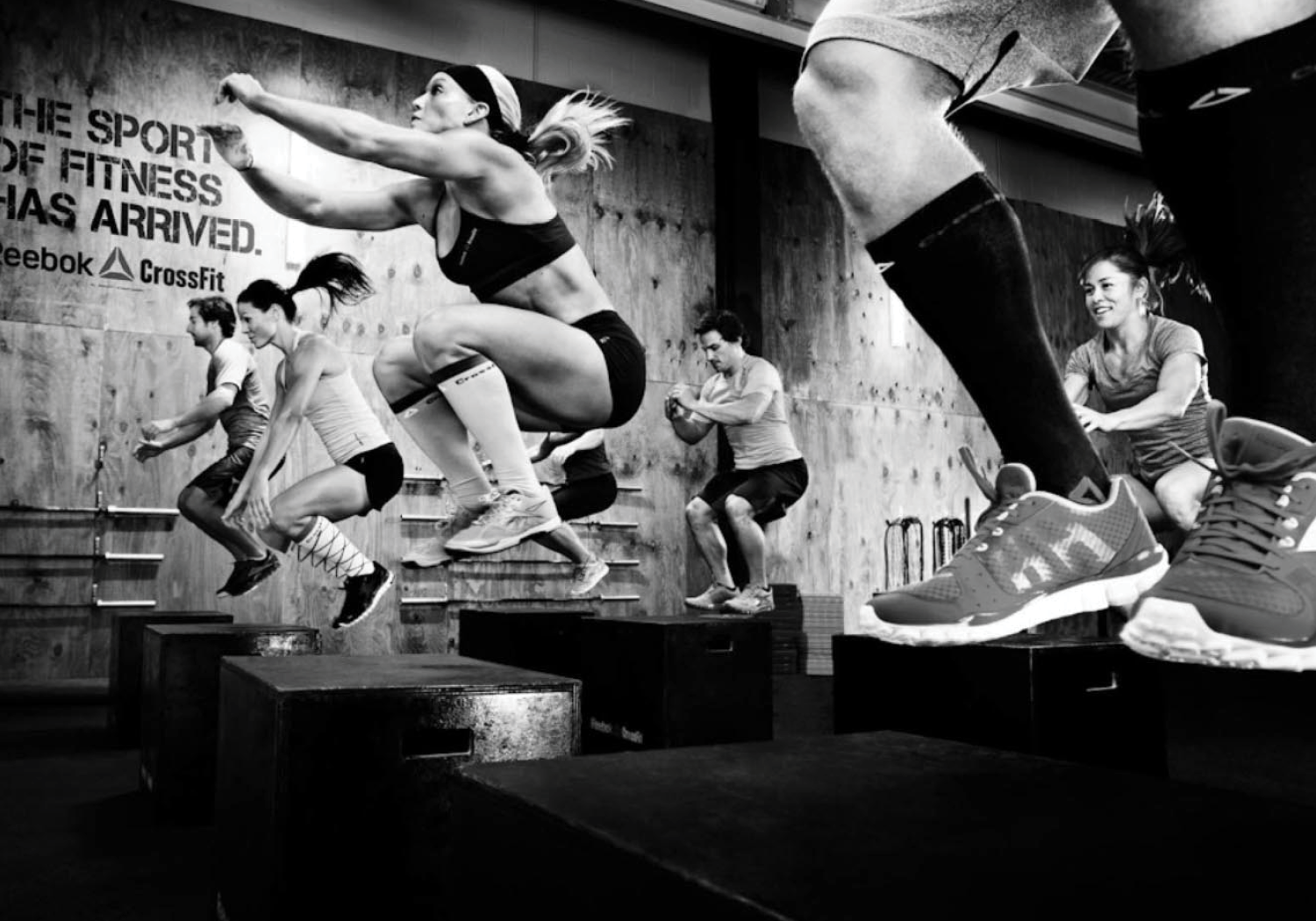

When putting together the final deliverables for Reebok, we had to work on the final deliverable, which would be the process book. It was important to keep a design aesthetic that would fit into Reebok’s existing graphic language as this process book would be used as an internal tool for the Reebok team to present back to their stakeholders to get funding for these ideas and recommendations.

The graphic board below shows some of Reebok’s graphics we used as a springboard to inspire our process book design language.

Visual Ideation

The next step was to ideate in different page layouts to use throughout our process book which you can see below. This would help us keep all the documentation organized.

Final Deliverables

After 10 weeks of hard work and collaboration between our teammates and the Reebok team, we managed to put together the following process book. Detailing our thought process and recommendations for Reebok to incorporate sustainable processes and designs into their line.

This tool was created to present our work back to Reebok, but was also then used internally at Reebok to open the dialogue with investors within company to fund this initiative. Flip through the pages of our book to get a better understanding of our project.

Spring 2015 / Savannah College of Art and Design