Michael Kors

Accessory Design at Michael Kors across multiple markets and platforms, including: Mainline, Wholesale, Outlet and Cut-up.

About

I’m a designer in a small team of two, in charge of all men’s accessories (belts, bags, wallets, hats) at Michael Kors. We design over 150 products per collection across four markets (Retail, Wholesale, Outlet and Cut-up) and over four seasons each year.

Process Overview

Role & Responsibilities

I’m in charge of driving the overarching design process for the Men’s Accessories Division including material sourcing and development, concepting, research, technical design, product development and factory communications. During my time at Michael Kors, I’ve worked cross-functionally with merchandising and production teams to ensure products are executed seamlessly while maintaining their design integrity.

Our Working Process

As a team, we have molded the way we work and adapted to a fast and iterative process. Since our team is so small, we have decreased the time spent on product development by 25%, increasing our bandwidth for ideation, design and experimentation.

Skill Development

I’ve also had the opportunity to work cross-functionally with merchandising and production teams, unofficially helping create a bridge between teams by taking on product development responsibilities, like material development, factory communications and pattern sharing and streamlining between manufacturers.

Design Process

We continually change the way we work to adapt to the ever changing demand in our products. But below, I have listed out the steps we typically follow each season when dropping a new collection and have shown examples of each:

Step 1: Ideation + Conception

The creative Director, gives our team high-level mood boards for 3 different deliveries. We then take these and interpret them through an accessory filter. We then create a board for each of the overarching delivery messages.

These boards contain images including: techniques ideas, silhouette inspiration, artwork and graphics, hardware finishes, trim and detailing, etc.

Step 2: Presentation + Alignment

We then take all of our market research and start the ideation process and show our ideas in the following ways:

Create new silhouettes and show these as greyscale, to show functionality and construction details

Use existing silhouettes and make Color CADs using material swatches

We then take the above and present it to senior leadership. This is repeated as often as necessary until we reach an agreement and everyone signs-off on our designs.

Step 3: Material + Graphic Development

Once we land on the concepts we will be designing into that season, we start material development and print development with our mills and tanneries.

We work with the Print and Pattern team to develop a print that fits into the overarching capsule that was given to us by our Creative Director, and then send it out for development.

We also put in different trials and executions of details and levels of novelty we can include in accessory platforms. For instance, if we know we want to make a varsity stripe program, we would put into work several panels showing different ways to execute a stripe so we can then decide on our favorite.

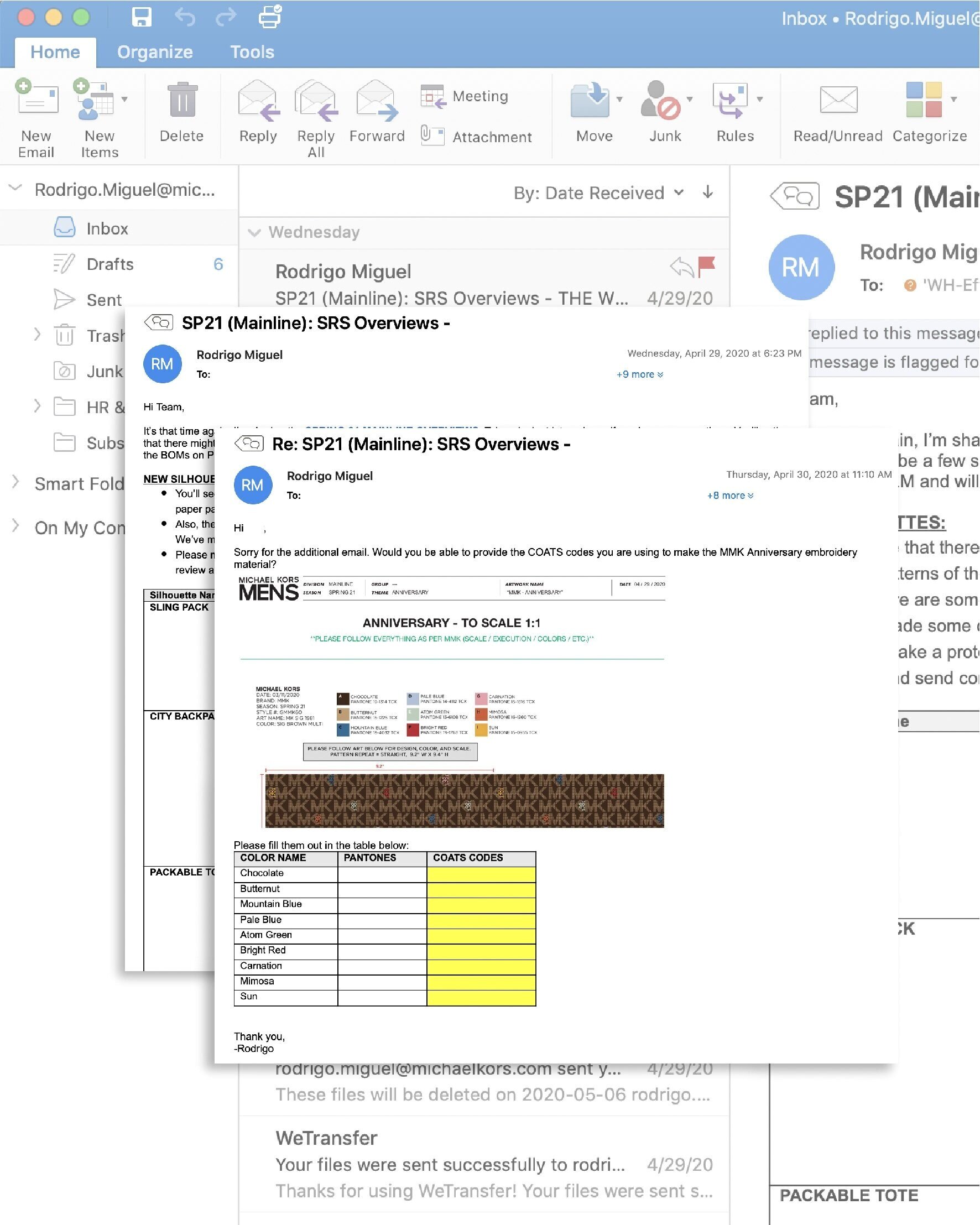

Step 4: Product Development

After concept and material development are done, all of the above comes together as we spec out each individual design and create what we call “Overviews”. These are one-pagers per theme containing color CADs, a BOM, and any specific comments.

These are then accompanied by Material Placement guides and sent over to the factories so they can place all material orders and put together the bags.

Step 5: Conception + Factory QA

The final step involves doing a Q&A with the factories as they make our samples. Normally factories get around a month to put together our showroom samples. So during this time, we provide support through email and video calls to clarify any of their questions/concerns.

After this, samples arrive, market week starts and we send any post-market comments and then these designs go into production and the process starts all over again.

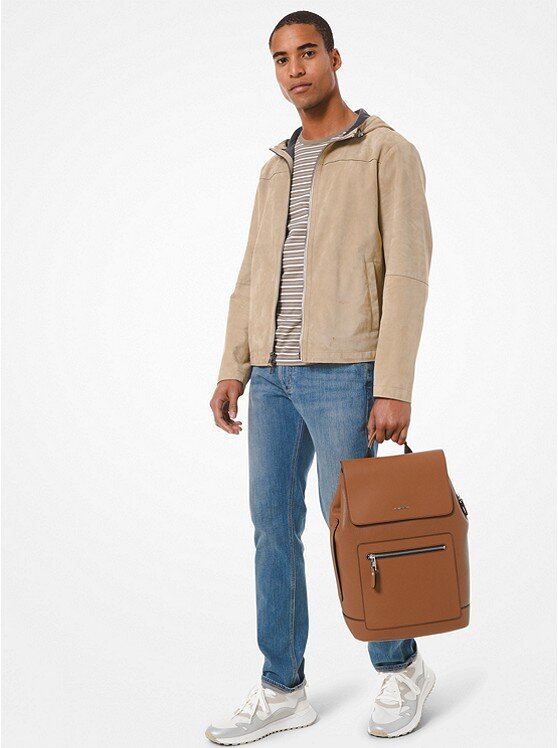

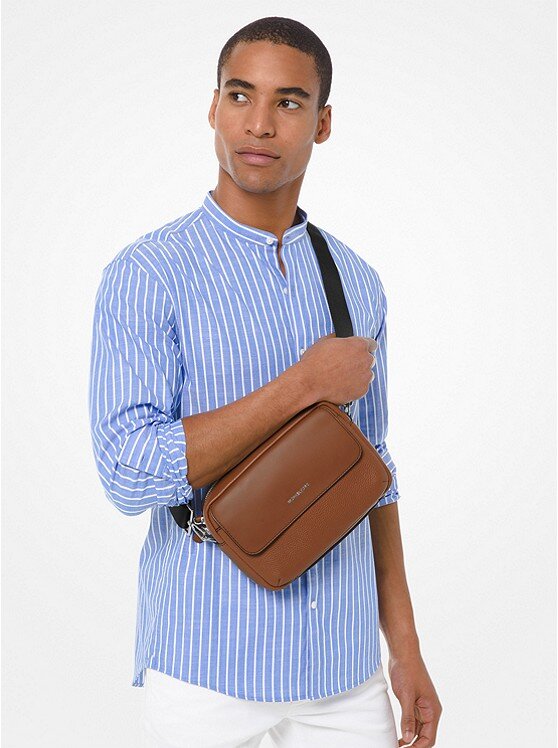

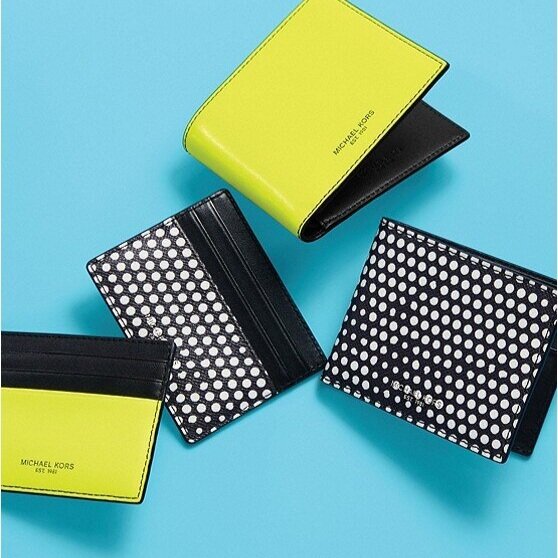

Examples of My Work

The below images are a few of the accessories I have designed in my time at MK. It is a mix of different seasons and categories.